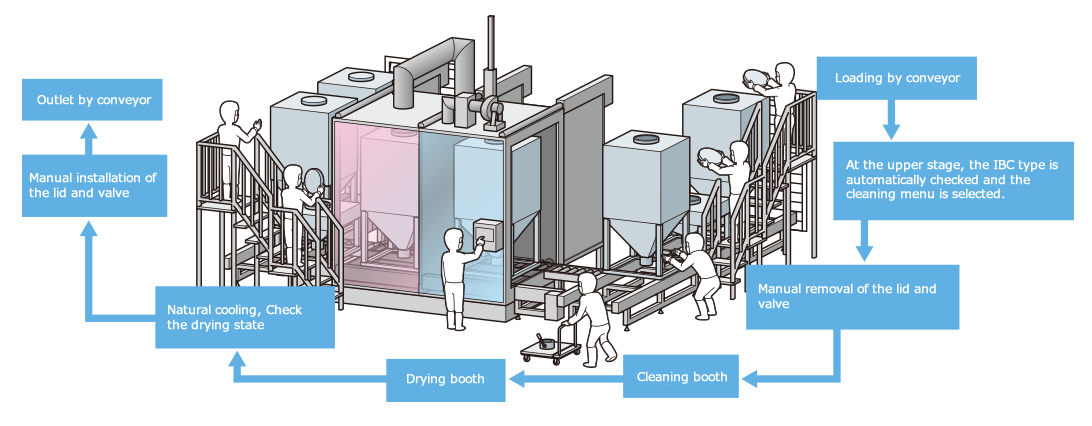

IBC Cleaning System

Automatic/2 booth type

Customer’s concept

□We request to clean and transport IBC without manual labor.

□Problem is that IBC has multiple sizes and various kinds of stain.

KIT design

□KIT introduces an automatic transportation type which operates together with the distribution facility.

□KIT practices cleaning and drying processes in two separate booths.

□KIT has wide selection from SUS 100L container up to 1800L IBC.

□KIT cleans with a washing pattern determined by each IBC.

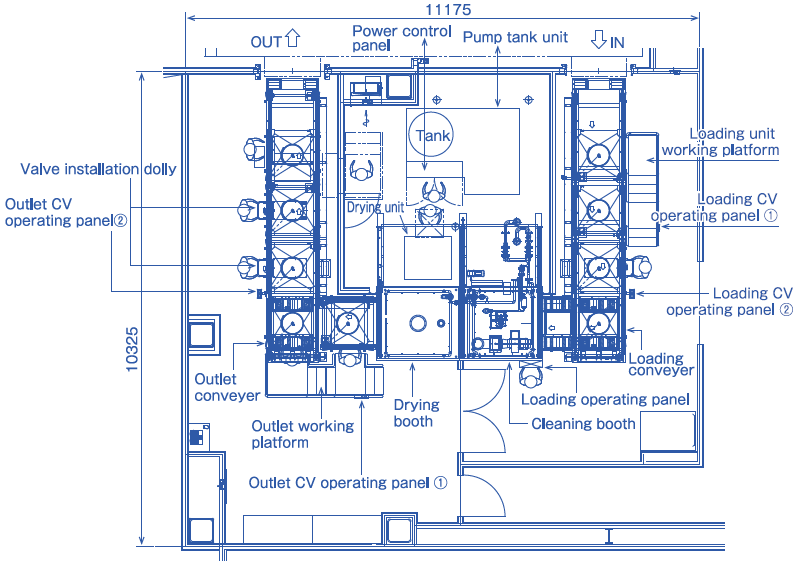

| Product specification example | |

|---|---|

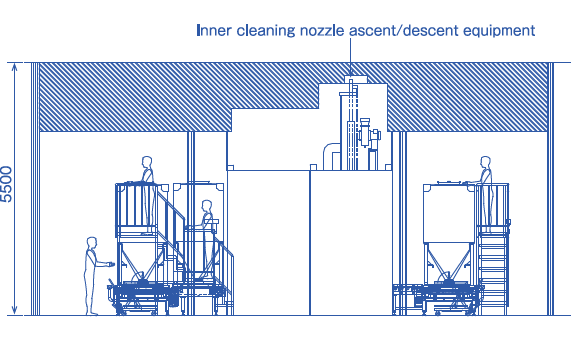

| Facility dimensions | W11175xD10325xH5500mm (Room size) |

| Weight : | Around 10.4 t (At the time the pump is filled with water) |

| Electrical Consumption | 30kW |

| Suitable IBC | 1800L・1200L・800L・400L for powder・400L for tablet |

| Cleanin | Hot water rough cleaning |

| Drying | Circulating hot-air blow method (together with a HEPA filter) |

| Operation: | control panel, touch panel |

| ※The specifications can be changed depending on the container form, inner structure and weight. | |

Introduction image

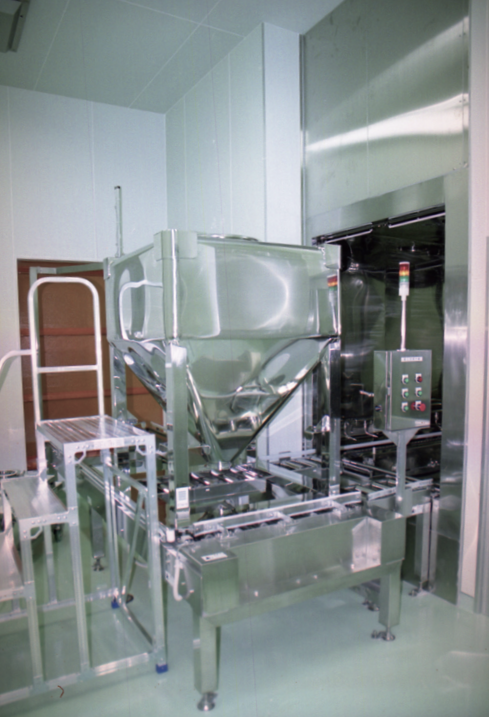

【Installed example】 IBC cleaning・drying equipment

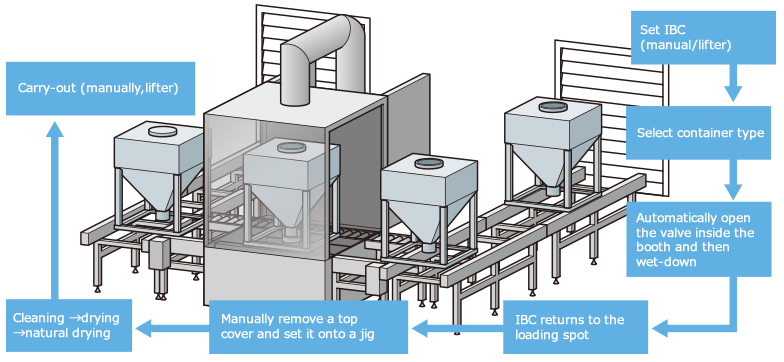

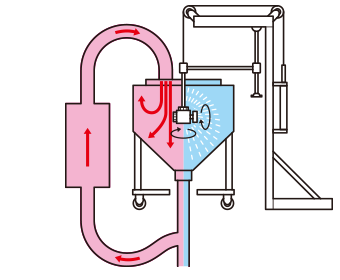

Operation flow

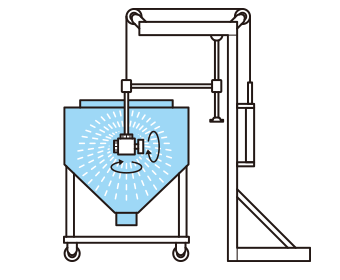

Design image

Design image

Automatic / 1booth type

Customer’s concept

□We request the facility to be as compact as possible.

□We request to clean highly active IBC container.

Examples of proposal and design of KIT

□KIT performs fine-tuned cleaning and drying according to the IBC shape and its characteristics within one booth

□KIT offers “wet-down” method compatible with highly active and general-use IBC.

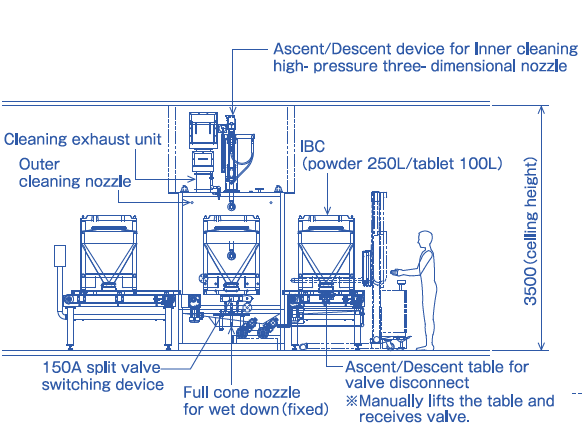

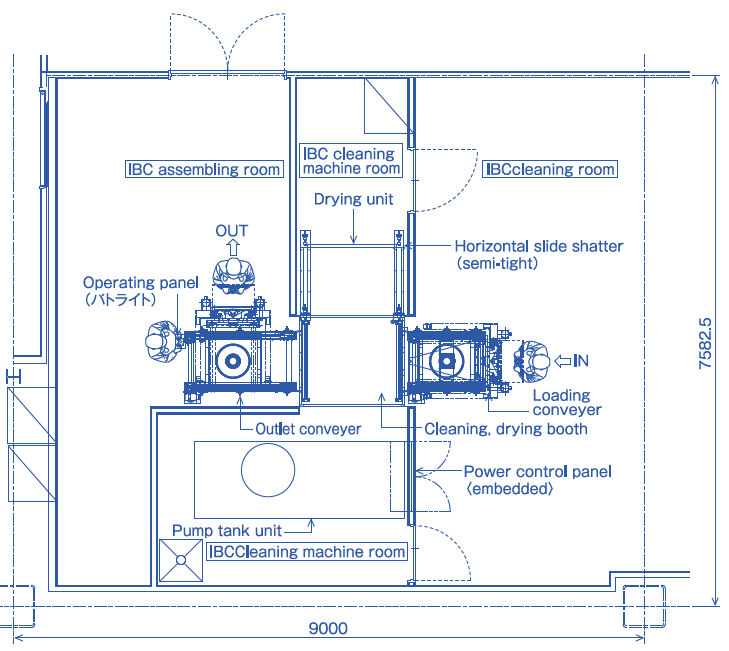

| Installed example | |

|---|---|

| Facility dimensions : | W9000xD7582.5xH3500mm (Room size) |

| Weight | 約9.2t (At the time the pump is filled with water) |

| Electrical Consumption : | 40kW |

| Suitable IBC | 250L for powder・ 100L for tablet/for highly active/for general pharmaceuticals, multiple use. |

| Cleaning | Inner IBC wet-down, Hot water rough cleaning, detergent cleaning, purified water rinse |

| Drying | Circulation method with HEPA |

| Operation: | Control panel, Touch panel |

| ※The specifications can be changed depending on the container form, inner structure and weight | |

Introduction image

【Installed example】 Cleaning system for highly active IBC container

Driving flow for Containment

Automatically open the valve inside the booth and then wet-down

Design image

Design image

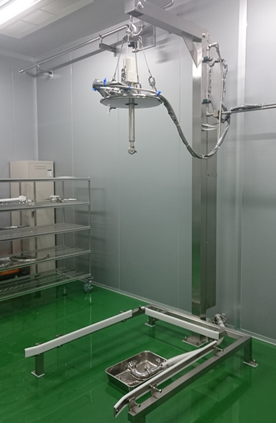

Simplified cleaning type

Inserting the nozzle into IBC for cleaning or drying

【Inner surface cleaning type 】

A simplified type. Simple to clean by inserting the 3D nozzle into the IBC.

【Inner surface cleaning and drying type】

Simple to clean and dry by inserting the 3D nozzle into the IBC.