IBC for granular material

IBC for GRANULAR MATERIAL

-

Product image

Row material handling container for such as pharmaceutical ・food.

Capable size : 50L~2000L

-

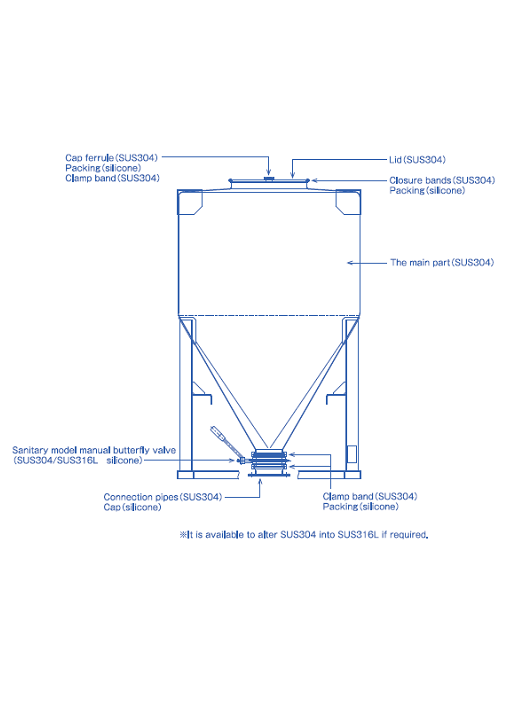

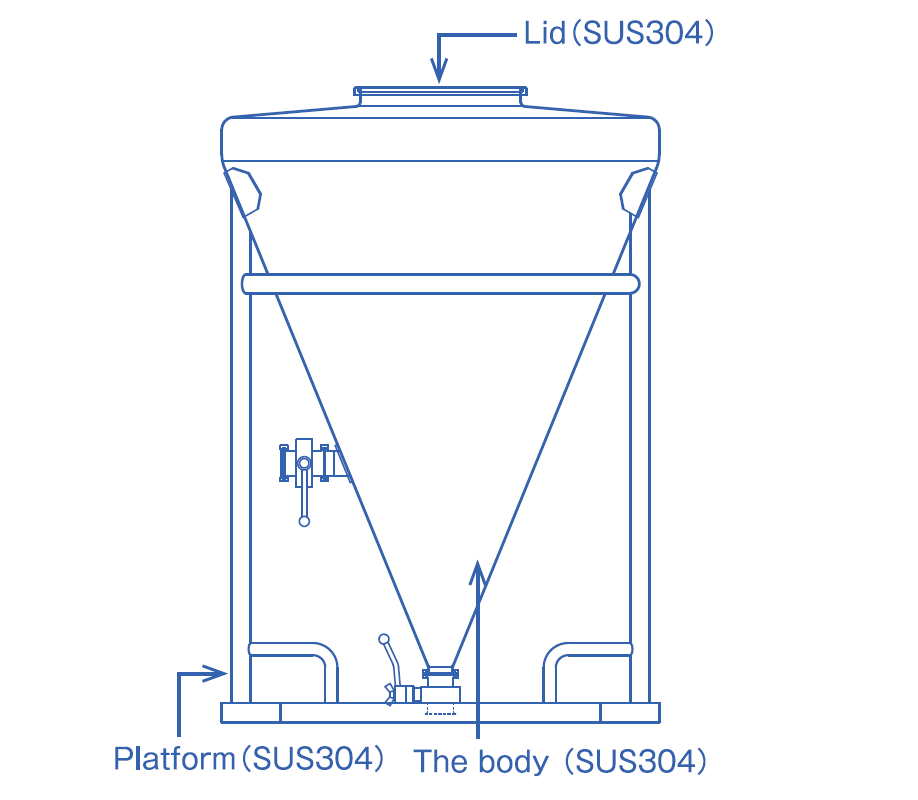

Design image

スクロールで図全体をご覧いただけます。

| Volume | Sizes mm(Available to produce other sizes.) | Standard specification | Option specification | Consumables | ||

| W | D | H | ||||

| 600L | 1100 | 1150 | 1200 | Interior #400 Exterior #240over |

●Material change

●With card holder ●Container change ●With ID tags ●With caster

●Bar-code label installation plate ●With exclusive dolly ●Air removing ferrule |

Packing Cap ※Please let us know the drawing number. |

| 1000L | 1100 | 1100 | 1530 | |||

| 1500L | 1100 | 1100 | 1950 | |||

| 2000L | 1100 | 1100 | 2380 | |||

IBC for TABLET

-

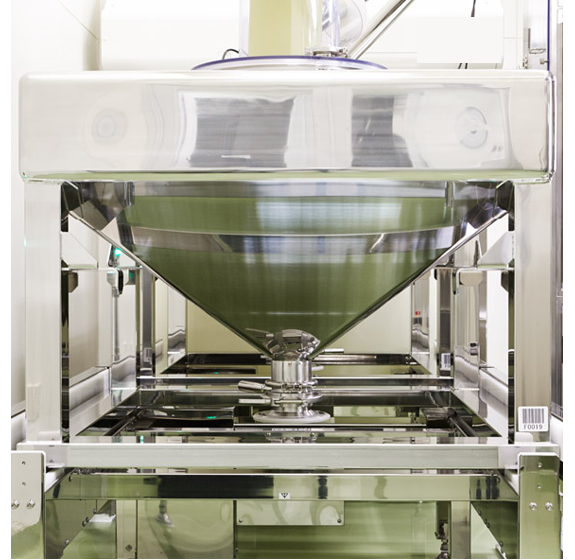

Product Image

Tablet/capsule handling container

Capable size: 300L~600L

-

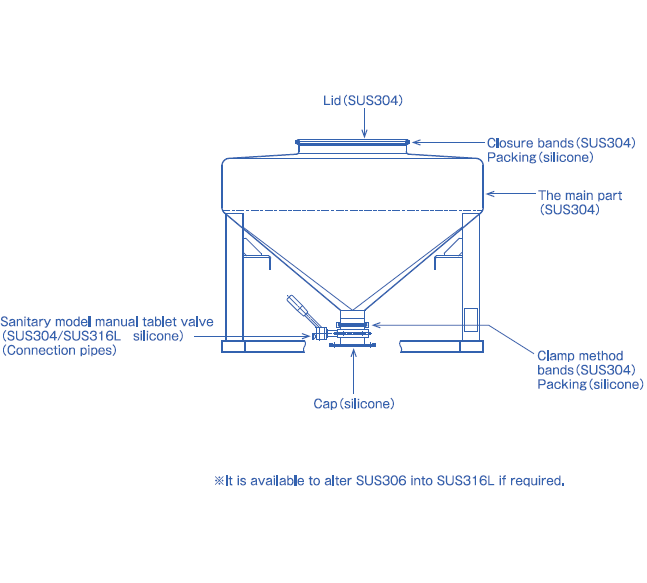

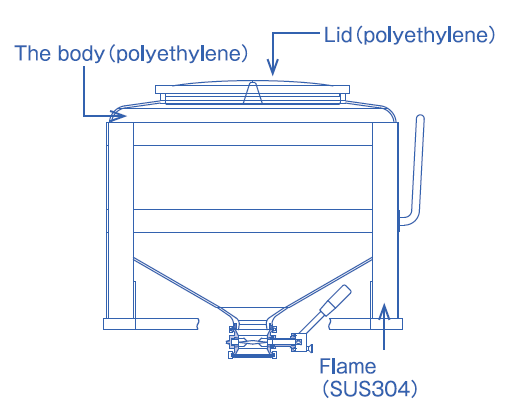

Design Image

スクロールで図全体をご覧いただけます。

| Volume | Sizes mm(Available to produce other sizes.) | Standard finish | Option specification | The expendables | ||

| W | D | H | ||||

| 300L | 1100 | 1100 | 760 | Interior #400+EP processing Exterior #240over |

●Material change

●With card holder ●Container change ●With ID tags ●With caster ●Bar-code label installation plate

●With exclusive dolly ●Air removing ferrule ●Electro conductivity PTFE lining treatment |

Packing Cap ※Please let us know the drawing number. |

| 500L | 1100 | 1100 | 930 | |||

| 600L | 1100 | 1100 | 1000 | |||

Other IBC(IBC for ointment, IBC for resin, Sanitary container)

■IBC for ointmentUse: Cylinder pressing container, Pyramid container.

-

Product Image

-

Design Image

■IBC for resinUse:tablet / capsule storage container

-

Product Image

-

Design Image

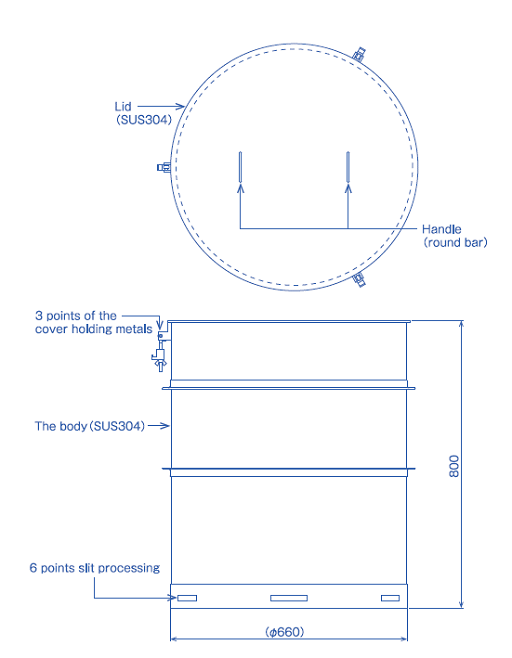

■Sanitary containerUse: pharmaceuticals, food, etc(10L~250L)

KIT produces sanitary containers with wide-ranging widths and shapes suitable for the customer’s use or handling method.

-

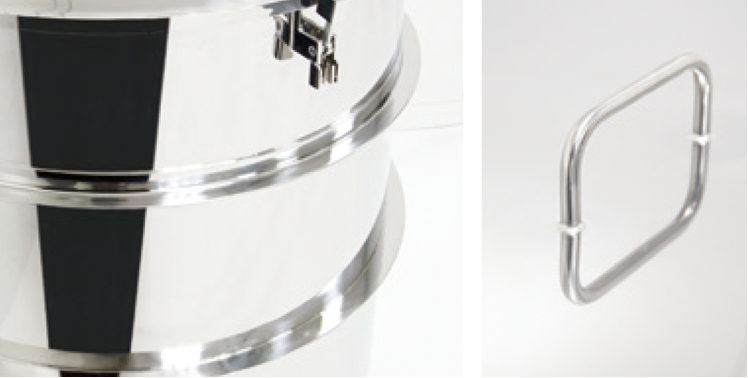

Product Image

example 250L sanitary drum can with exclusive dolly

-

Design Image

●The smooth surfaces do not allow water or other foreign substances to accumulate.

-

Welding is done entirely on the flanges and handles. This optimizes cleaning efficiency.